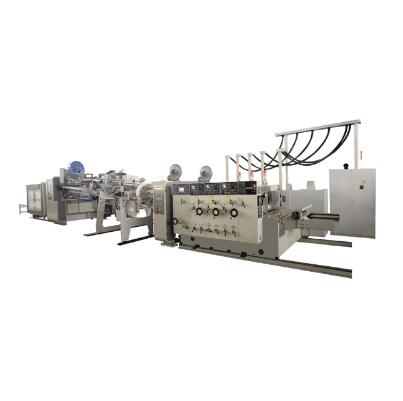

Automatic Slitting and Rewinding Machine

Introduction:

Introduction:

This Slitting and rewinding machine is widely used for slitting white board paper, carbon-free paper, coated paper, two-side offset paper, etc. It is high speed with 400m/min which can cut 30-510gsm paper and other film materials

More details

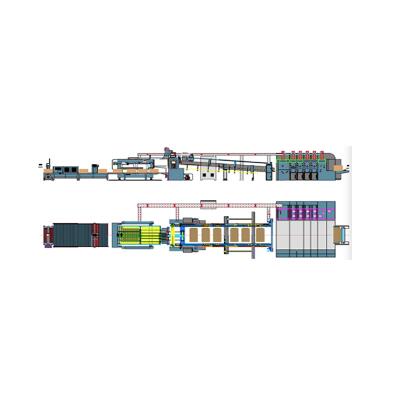

High speed Automatic Paper and Film Slitting Machine

Introduction:

Introduction:

This Slitting and rewinding machine is widely used for slitting white board paper, carbon-free paper, coated paper, two-side offset paper, etc. It is high speed with 400m/min which can cut 30-510gsm paper and other film materials

Main Parameters:

|

Material type: |

white board paper, carbon-free paper, coated paper, two-side offset paper, etc. |

|

Material thickness: |

30-510g(paper) |

|

Max. Diameter of raw material: |

1800mm |

|

Raw material paper core: |

3#, 6# |

|

Max. Width of raw Material: |

1800mm |

|

Min. Width of Raw Material: |

400mm |

|

Roller surface width: |

1850mm |

|

Width of slitting: |

40-1800mm |

|

Rewinding paper core: |

3# |

|

Max diameter of rewinding: |

1500mm |

|

Error-correction length: |

150mm |

|

Precision: |

±0.15mm |

|

Max. Speed: |

400m/min |

|

Slitting speed: |

10-400m/min |

|

Total power: |

52KW |

|

Total weight: |

18000kg |

|

Dimension: |

7500mmx4200mmx2300mm |

|

Slitting tools: |

10 sets for standard, also can do according to customer’s requirement. |

|

Upper slitter dimension: |

Φ160*100*50mm Brand: shanghai shenlong |

|

Bottom round cutters dimension: |

Φ150*120*40mm Brand: shanghai shenlong |

|

Rewinding shaft with 2pcs of 3# air shaft, recycle using. |

|

|

This equipment is with 13pcs if Φ120 aluminum roller, 1pcs of rubber roller and 1pcs of steel roller. |

|

|

With 2pcs of round cutter shaft |

|

Function description

Unwinding part

- ► Adopts shaftless hydraulic fixing system, easily for one person operation. Using special conic node system from 3” to 6” for durable using. The 2 sides clamping arm are controlled by the hydraulic dovetail groove linear guideway. 2pcs of hydraulic clamping oil cylinder moves to each side at the same time, easily operation.

- ► 2pcs of hydraulic type loading and unloading material oil cylinder can bear 3T material to save the manpower and time.

- ► It does not need to input the material thickness, the proximity switch can inspect the unwinding diameter directly which near the transmission shaft. The machine can slow down according to the rest material, in this way, the worker can prepare for the next roller. The unwinding tension adopts the sensor close-cycle automatic tension, controlled by PLC.

- ► With the manual adjustment system, the unloading material tightness can be controlled. The adjustable range: +/-20mm

- ► Automatic error-correction for the edge position is controlled by the CCD photographic system. The whole frame adopts guide way type to move left and right which driven by the servo motor. The moving part uses thread screw.

- ► Pneumatic material connecting device, with the square steel structure, adopts the way of pneumatic and rubber pressing roll to save the material

- ► Bridge type feeding materials

- ► The unwinding adopts the Italy pneumatic braking.

- ► Precision proportional valve use SMC

Main body part

- ► The bare frame uses the 80# casting material, easily for dismounting and transportation.

- ► The transmission combines the servo motor with synchronous wheel speed ratio.

- ► Automatic traction device adopts pneumatic pressure way. The servo motor drives the mirror roll.

- ► Close-cycle vector control.

Rewinding part

- ► With double structure of surface rolling and center rolling, rewinding by front and back(A/B shaft), double air shaft way( also can be single rewinding).

- ► Clamping arm uses imported dovetail groove linear guideway

- ► The rewinding shaft clings to the steel shaft( the steel shaft is driven)

- ► Each bearing with 1 set of 18.5KW servo motor to drive the air shaft. The tension decided by the roll diameter. PLC controls frequency converter automatically to adjust the tension of the air shaft to make all the sheet same thickness when do the multiple slitting. Because of the press roller, all the reels end face is smooth. it has the choice of pneumatic press roller and self-weight press roller. The degree of the tightness of the finished products can be adjustable. With the increasing of the rewinding diameter, the servo motor speed goes down to extend the life of the air shaft.

- ► It also can choose the whole shaft tension and the servo motor in torque control mode in PLC

- ► Discharging type: automatic hydraulic

- ► Waste paper recovery device: Using motor to blow out the waste paper more than 20m. (also can choose the automatic tatter function). The net cage should be prepared by customer.

Machine photo:

-

Corrugated Paperboard Production Line

-

Single Facer Line

-

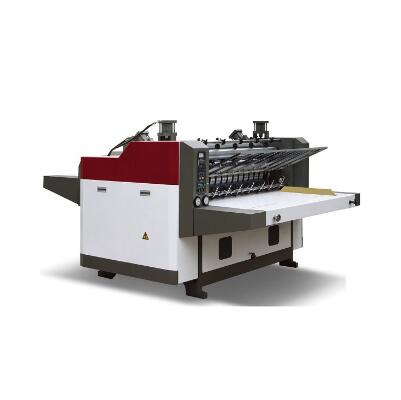

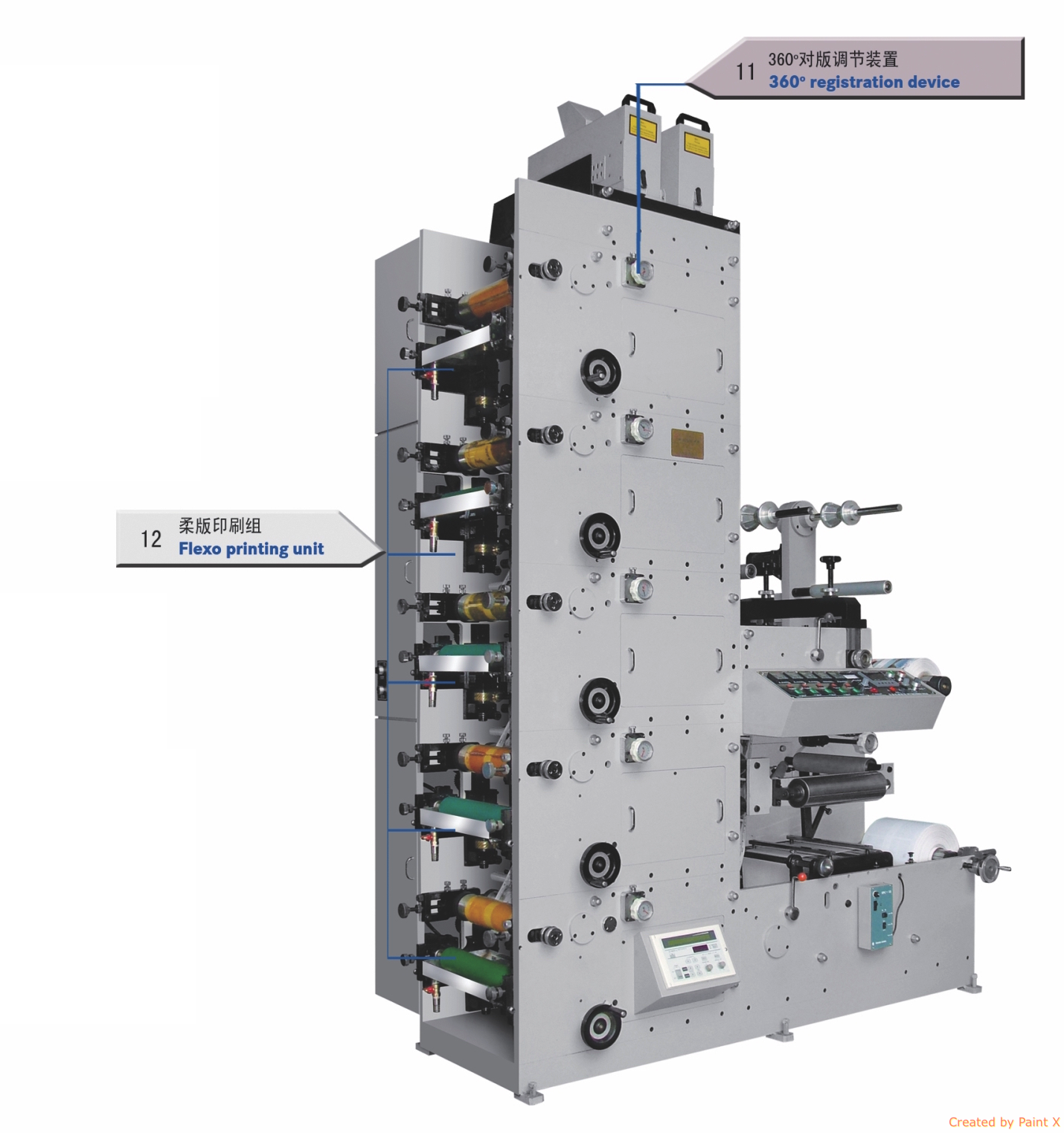

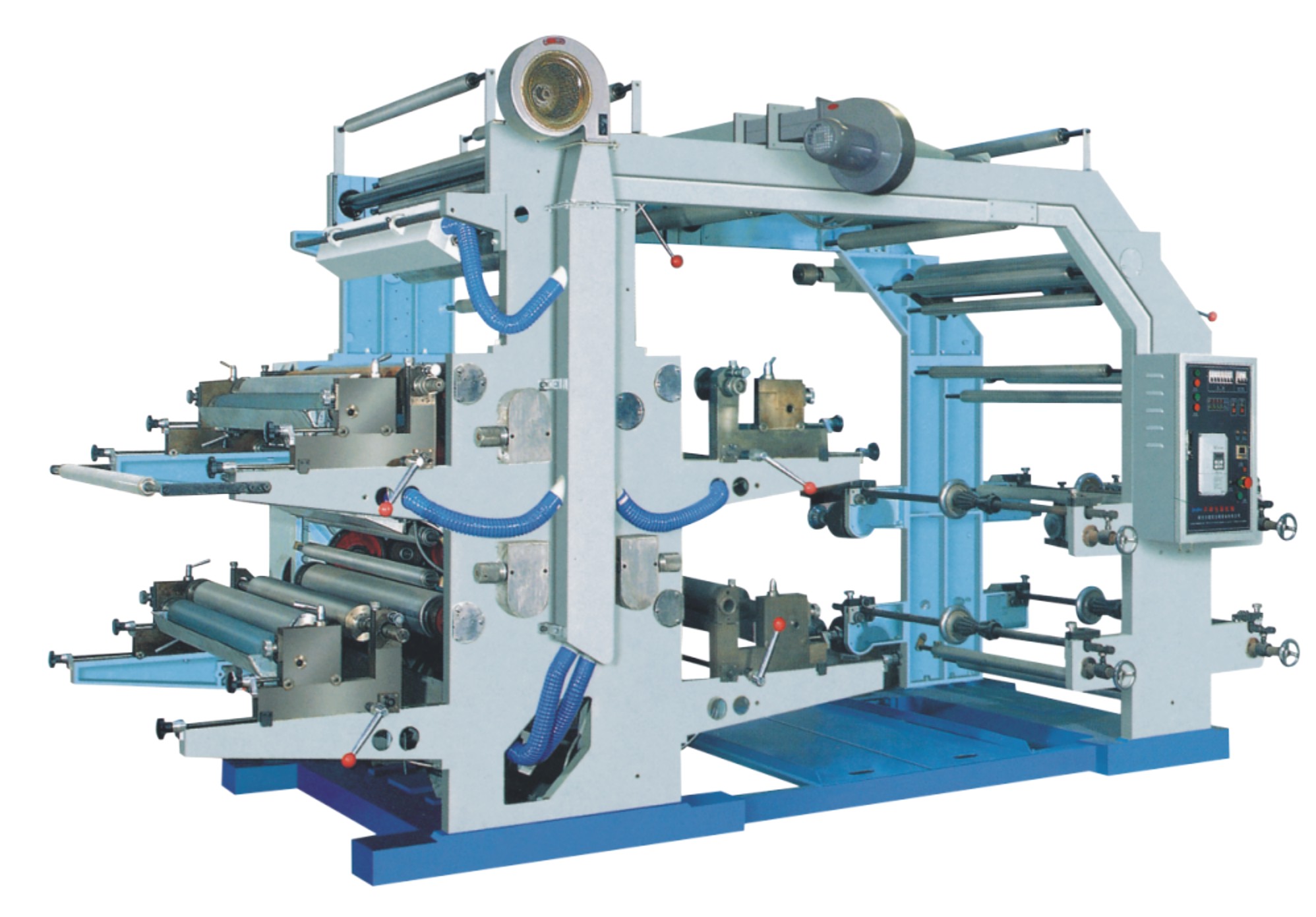

Flexo Printing Machine

-

Folder Gluer Machine

-

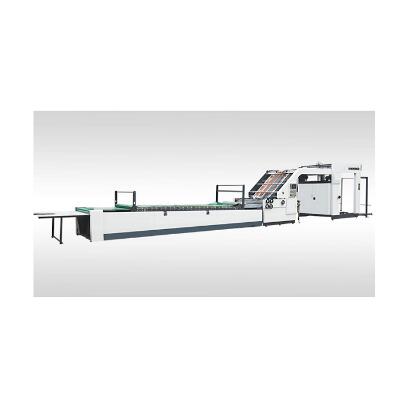

Flute Laminating Machine

-

Flat Die-Cutting Machine

-

Rotary Die-Cutting Machine

-

Carton Stitcher Machine

-

Paperboard Waste Baler Machine

-

Paperboard Stripping Machine

-

Single Facer Machine

-

Slitter Scorer

-

NC Cutter

-

Paper Roll Stand

-

Paperboard Stacker

-

Flexo Printing Plate Making Machine

-

Die-Cutting Mould Making Machine

-

Other Machines and Spare parts

-

Paper Roll Cutter

-

Window Patching Machine

-

Embossing machine

-

Slitting and Rewinding Machine

-

Paper Box Making machine

-

Digital Printing Machine