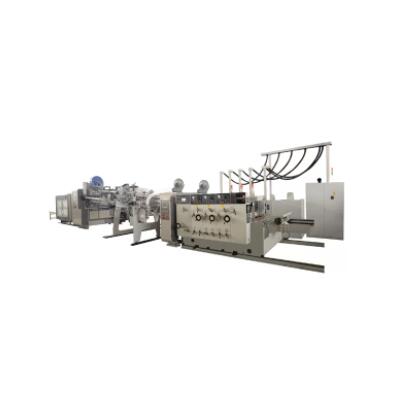

MJSF-280OE Single facer (Oil/electrical heating Exchange)

Introduction:

Single Facer is the main machine for producing the corrugated paperboard. Vacuum suction model single facer has very good production precision. The choose of the machine is directly effecting the quality of the corrugated paperboard.

※Structural features:

★Design speed: 100m/min

★Effective width: 1000mm ~ 2500mm

★Using suction hood structure, with a strong high pressure blower, suction with a silencer. Gas supply and electrical control centralized in the same operation panel, not less than 1.5 meters from the hosts, operating side cover closed.

★Cast iron wallboard, siding thickness of 130mm. Universal Joints.

★Corrugated roller material adopt 48CrMo alloy steel, after quenching, intermediate frequency quenching, surface polishing,corrugated main roller diameter¢ 280mm,surface hardness more than HRC58 degrees,airbag loading. The key parts of the tile and pressure roller bearings high temperature bearings Wafangdian production.

★Pressure roller¢ 284mm, Surface grinding and chrome plated; airbag load, the material is medium carbon steel 45, quenched and tempered.

★Pneumatic control for glue, back glue,glue roller diameter ¢215m. Engraved polishing surface after pit style textured machined hard chrome plating process, scraping the roller surface after polishing hard chrome plating.

★Corrugated roller, pressure roller materials provided by the Central Plains Steel, corrugating unilateral 0.15mm high, the pressure roller unilateral 0.075mm high.

★preheat roller with Day steel production seamless Steel Tube¢ 320mm.

★Using four sets of electric heating pipe heating oil, heating fast, no furnace, automatic temperature control and two groups control.

★Conducting oil powerful closed-loop circulation system pressure is low, no leakage, heat recycling, less heat loss.

★Installed in the special structure of the heat roller churning ring, roller heat evenly, corrugated good shape.

★Conducting oil high thermally conductive, carrying high-calorie, simple production process, low investment, for small carton production.

Technological Parameters:

|

Working Width |

1200mm |

1400mm |

1600mm |

1800mm |

|||

|

Heating method |

Oil heating & Electrical heating |

||||||

|

Design speed |

80m/min |

||||||

|

Economical speed |

40-50 m/min |

||||||

|

Compress-air pressure |

0.4-0.9MPa |

||||||

|

Flute type |

Standard flute |

UV Flute |

|||||

|

Standard spec. |

A,B,C,E,F |

||||||

|

For other type and model, we can produce as customer’s requirement. |

|||||||

|

Corrugated roll diameter (mm) |

280 |

||||||

|

Wall Thickness (mm) |

130 |

||||||

|

Type |

Vacuum Absorb |

||||||

|

Roller material |

48CrMo alloy, Heat treated |

||||||

|

Machine Size (mm) |

3300*1300*1700 |

3550*1300*1700 |

3800*1300*1700 |

4050*1300*1700 |

|||

HS CODE: 844180900

-

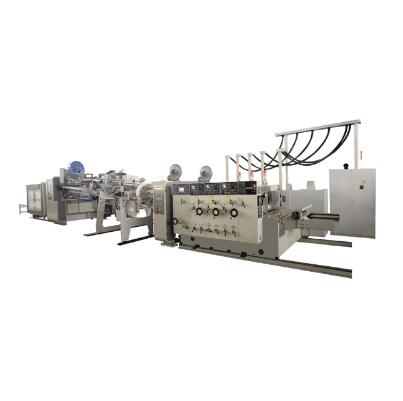

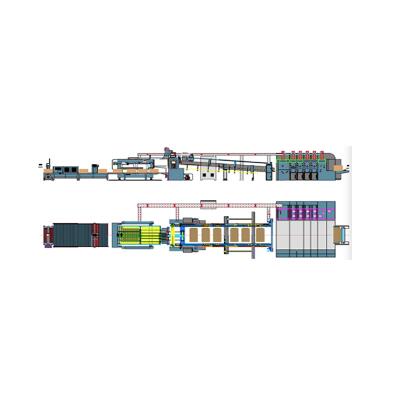

Corrugated Paperboard Production Line

-

Single Facer Line

-

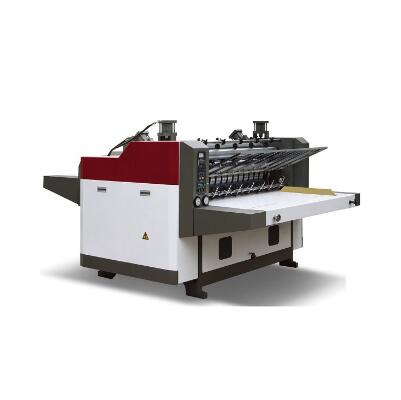

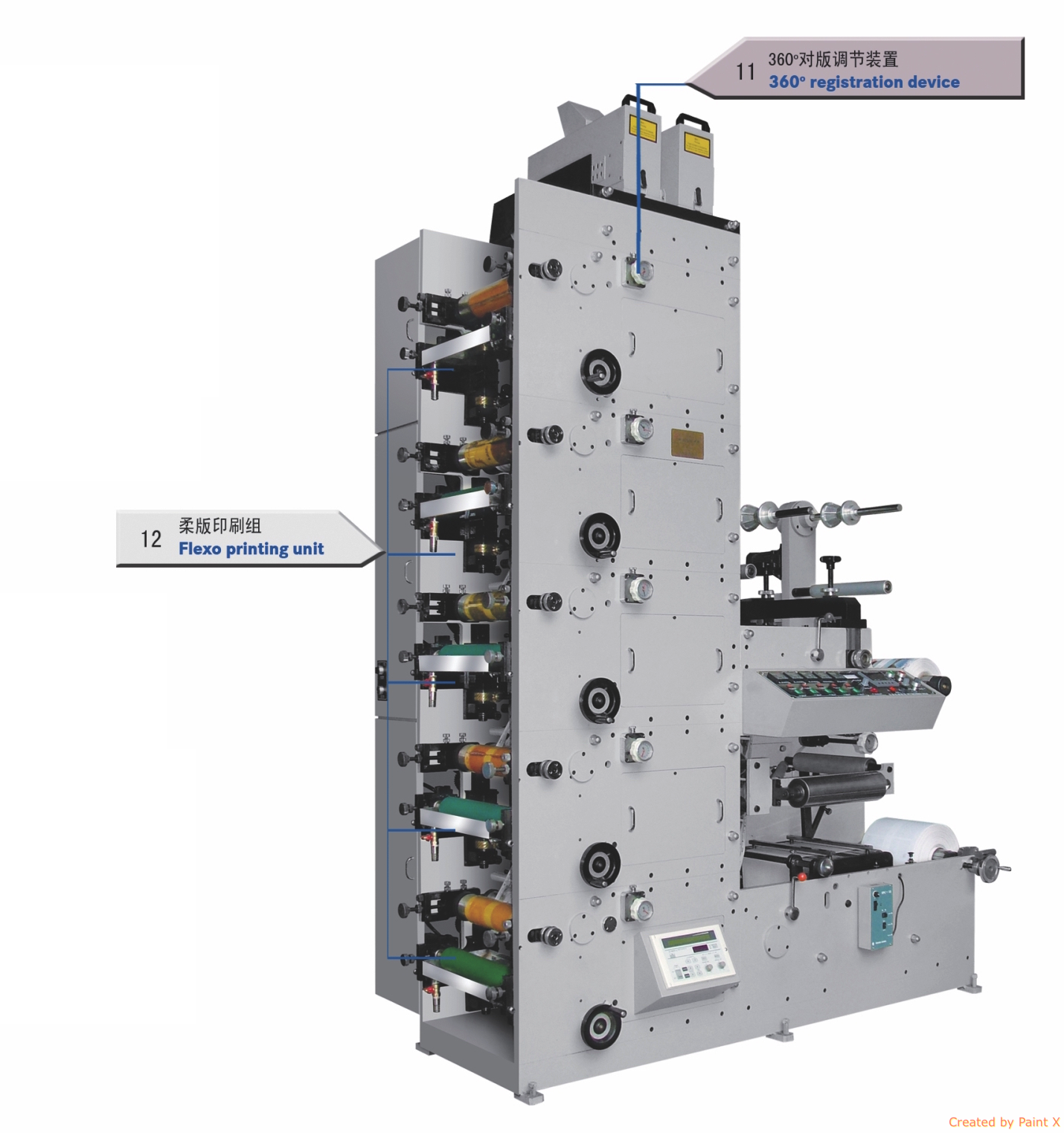

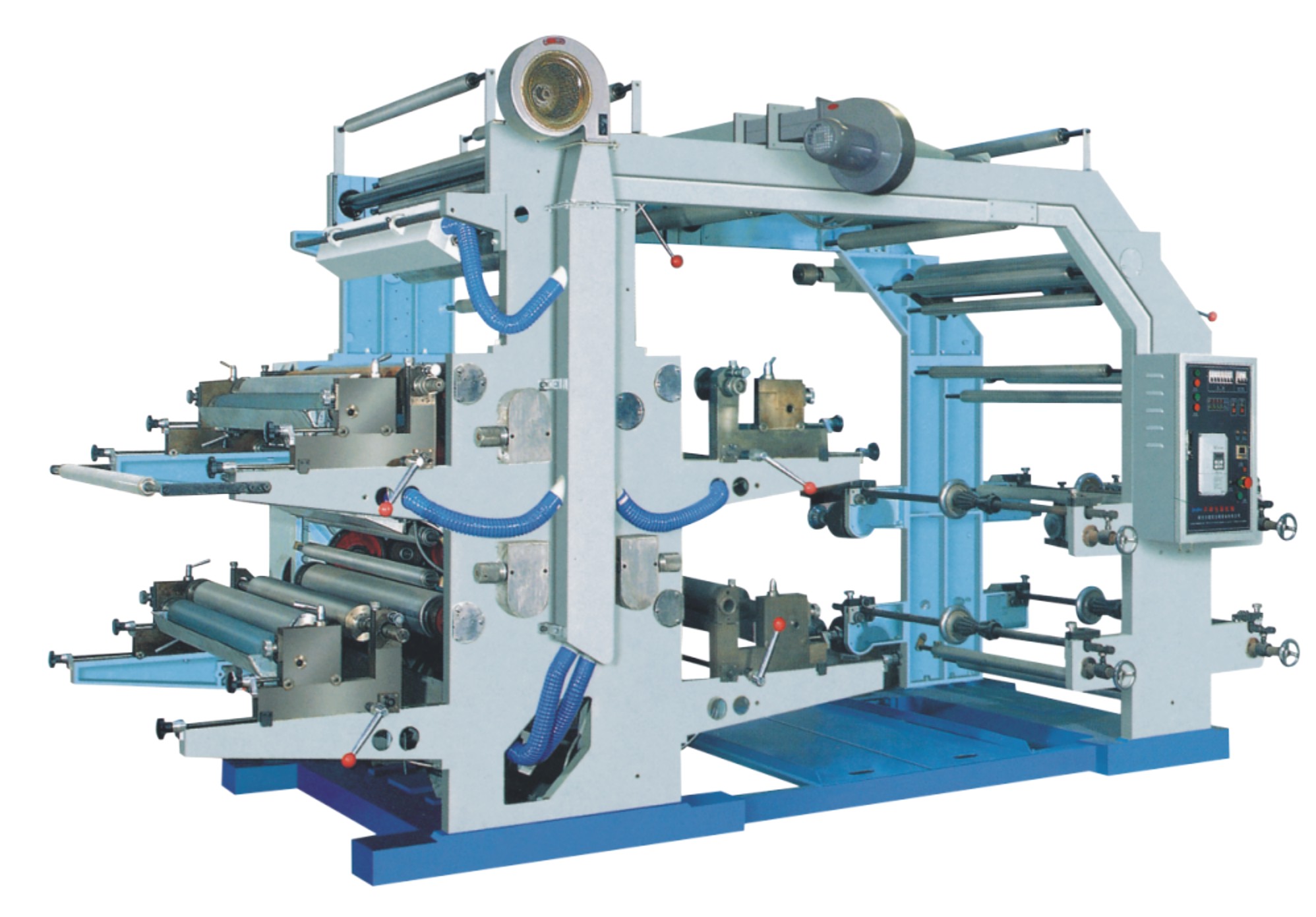

Flexo Printing Machine

-

Folder Gluer Machine

-

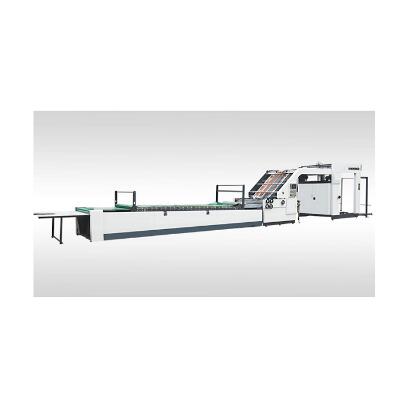

Flute Laminating Machine

-

Flat Die-Cutting Machine

-

Rotary Die-Cutting Machine

-

Carton Stitcher Machine

-

Paperboard Waste Baler Machine

-

Paperboard Stripping Machine

-

Single Facer Machine

-

Slitter Scorer

-

NC Cutter

-

Paper Roll Stand

-

Paperboard Stacker

-

Flexo Printing Plate Making Machine

-

Die-Cutting Mould Making Machine

-

Other Machines and Spare parts

-

Paper Roll Cutter

-

Window Patching Machine

-

Embossing machine

-

Slitting and Rewinding Machine

-

Paper Box Making machine

-

Digital Printing Machine