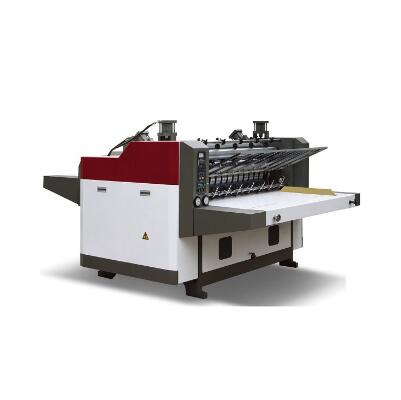

High Speed Casette Single Facer MJSF-320D

*EASY CHANGE FLUTE

*TOUCH SCREEN CONTROL SYSTEM

*MOTORIZED ADJUST GLUE UNIT AND INVERTER CONTROL

* STABILITY OF AIRBAG CONTROL SYSTEM WITH PNEUMATIC CONTROL BUFFER EFFECT

Machine Introduction:

--Design Speed: 180m/min

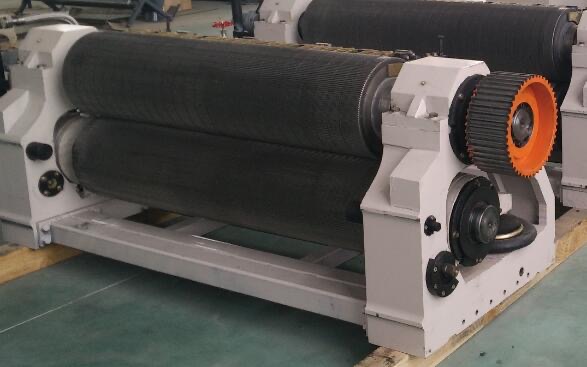

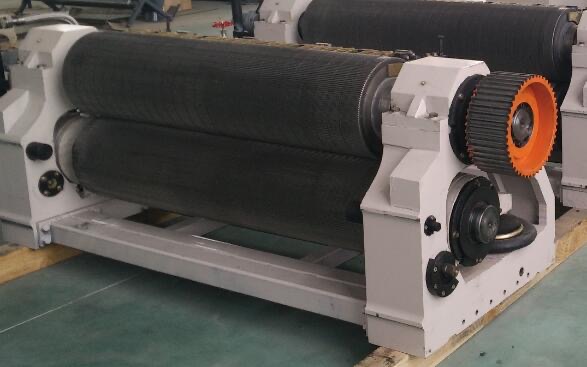

--Fingerless vacuum suction type single facer, the upper and lower corrugated roller made of 48 CrMo alloy steel, with harted treatment, the hardness is above HRC58o-60o.The surface is well treated by grind and tungsten carbide coated.

--Using negative pressure type design helps the medium paper to press evenly and closer to the surface of corrugating roll to have perfect forming. And also get even gluing on the flute tip to have perfect laminating of the single facer.

--Quick change rolls in 15 minutes, while replacing the corrugated rolls, the whole complete set of additional rolls with cassette is delivered into he machine by the carriage and matched with the hydraulic motor to be fixed on the base of the machine by hydraulic system. Quickly and easily complete the corrugated roller replacement.

--The corrugating roller is made of 48CrMo high quality alloy steel, using heat-treatment. Surface plates hard chromium after grinding.

--The corrugating rolls, pressure roll, and glue roll are adopted with High stability of the airbag control system, also with pneumatic control buffer effect.

--Adopt Glue width motorized dividing to match the paper width. Idle running motor for glue applicator roll to avoid glue dry. Adjustment for gap between glue roller and doctor roller by electric . Digital read out for the gap between glue roll and doctor roll.

-- The moveable type glue unit is convenient to clean and maintain.

-- Easy operation control system. Touch screen with colorful drawing displays operation state, easy and simple to handle.

--Built-in pre-conditioner with proportional spraying device for the medium moisture and temperature adjustment.

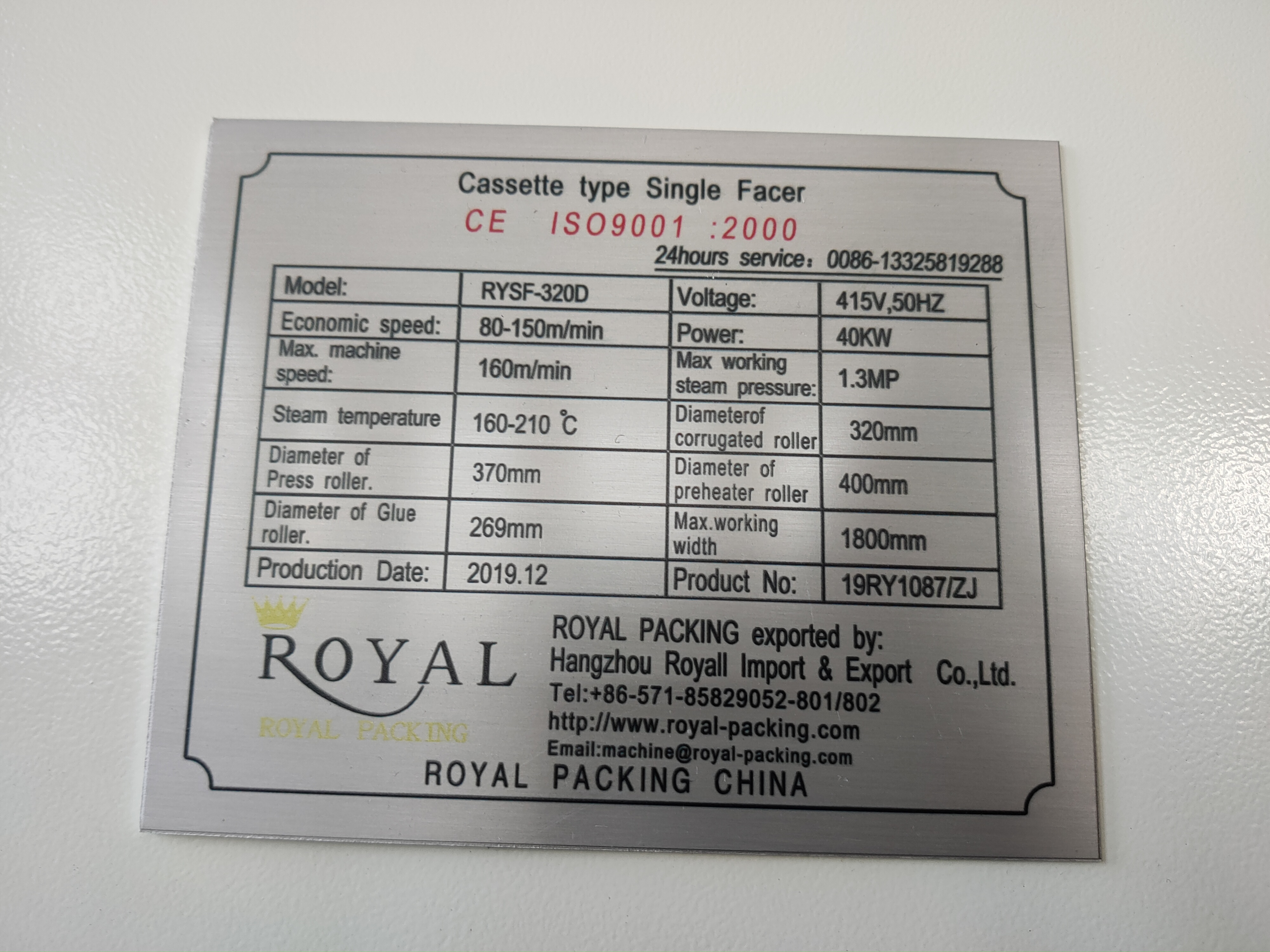

Technological Parameter:

|

Max. machine speed |

180m/min |

|

Economic speed |

150m/min |

|

Max. working width |

1050mm ~ 2250mm |

|

Max working steam pressure: |

1.0-1.3Mpa |

|

Steam temperature |

160 ~ 210 Degree |

|

Power requirements: |

380V, 50Hz |

|

Diameter of corrugated roller |

320mm |

|

Diameter of Press roller . |

360mm. |

|

Diameter of preheater roller |

360mm |

|

Diameter of Glue roller |

242mm |

|

Diameter of doctor roller |

118mm |

-

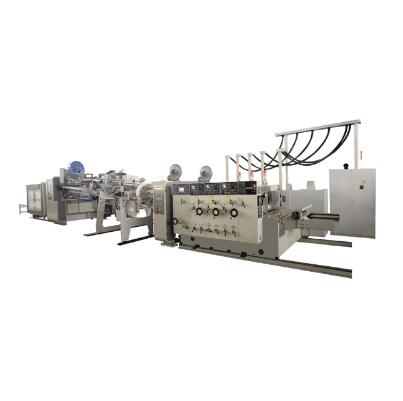

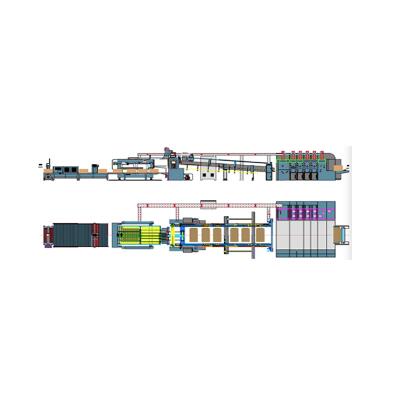

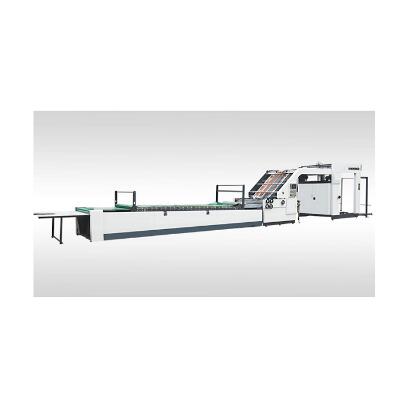

Corrugated Paperboard Production Line

-

Single Facer Line

-

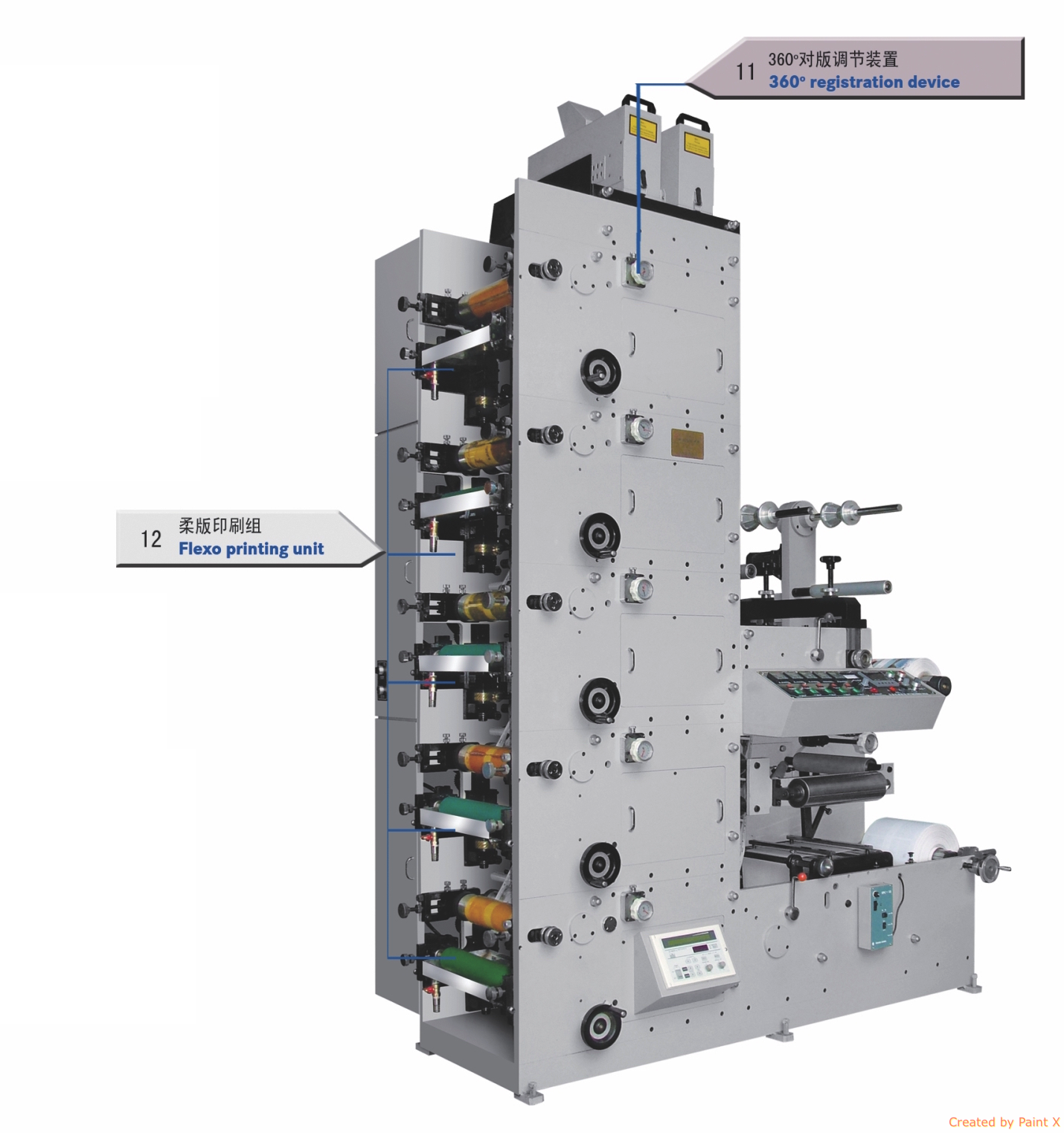

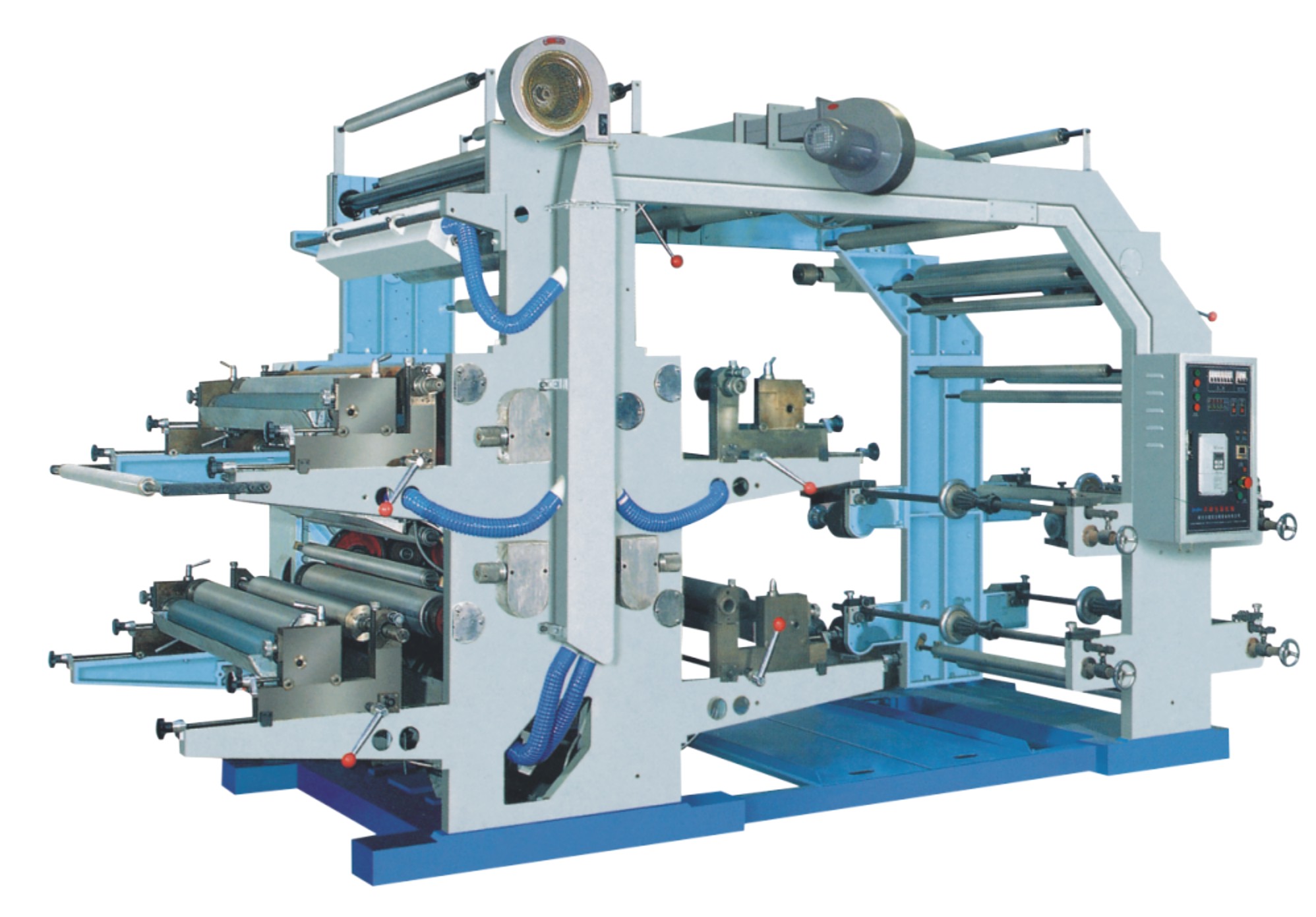

Flexo Printing Machine

-

Folder Gluer Machine

-

Flute Laminating Machine

-

Flat Die-Cutting Machine

-

Rotary Die-Cutting Machine

-

Carton Stitcher Machine

-

Paperboard Waste Baler Machine

-

Paperboard Stripping Machine

-

Single Facer Machine

-

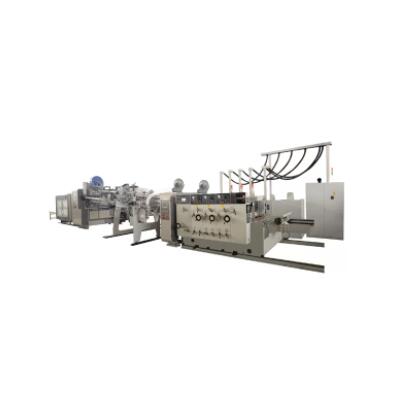

Slitter Scorer

-

NC Cutter

-

Paper Roll Stand

-

Paperboard Stacker

-

Flexo Printing Plate Making Machine

-

Die-Cutting Mould Making Machine

-

Other Machines and Spare parts

-

Paper Roll Cutter

-

Window Patching Machine

-

Embossing machine

-

Slitting and Rewinding Machine

-

Paper Box Making machine

-

Digital Printing Machine