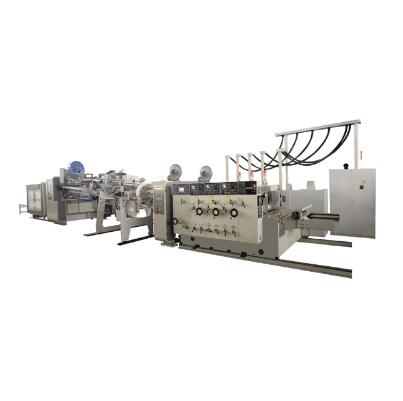

Royal Packing High Speed Sheet Cutter Machine

Introduction:

ROYAL PACKING is professional producer for Sheet Cutter apply the advanced technique of Germany and England. The computer control system apply AC servo motor and AC transducer. The conveyer belt apply NITTA from Japan. The pneumatic vibrator apply FINOLEVA from Switzerland. The electrical system adopts MOELLER&OMRON, the speed of cutting paper is fast and stable. Germany precise bearing and cutting knife assure the high cutting precision.

More Details:

RYG Servo Precision High Speed Sheet Cutter Machine

Features of RYG series include:

Features of RYG series include:

- ► Main drive system: AC servo motor

- ► Two sets of Automatic anti-curve devices

- ► Anti-static device

- ► Human machine interface

- ► Automatic tension control system

- ► Wide cutting thickness from 60-550gsm

- ► Photoelectrical device for safe operation

- ► ISO9001 and CE approved manufacturing process

- ► European, Taiwan and Japanese standard spare parts

Processed Materials:

Specification:

|

Model |

RYG-1400/1700/1900 |

|

Model of cutting paper |

The upper knife cut reciprocally and the down knife is fixed |

|

Thickness of cutting paper |

60-550GSM (per thickness of per paper are need >60GSM; Total thickness of all paper are need <550GSM) |

|

Max. scroll diameter |

1800mm |

|

Cutting length range |

450-1600mm |

|

Cutting precision |

Cutting length <=1000mm: +-0.5mm; Cutting length >1000mm: +-0.1% ; |

|

Max. cutting meter speed |

350m/min |

|

Max. Paper piling height |

1500mm |

|

Max. Paper cutting width |

1400mm/1700mm/1900mm |

|

The request for air compressor |

0.8Mpa |

|

Power consumption |

380V/50Hz |

|

G.W. |

13000kgs |

Machine’s Detail:

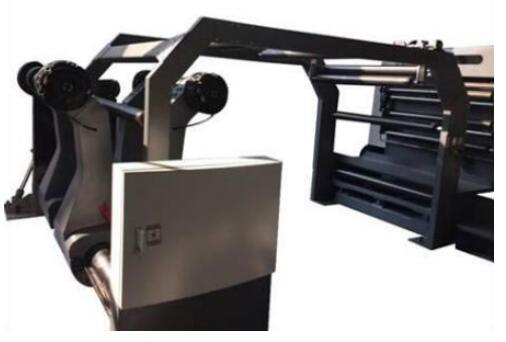

SHAFTLESS MILL ROLL STAND

Hydraulic drive:

- ► Open/close and forward/backward movement of paper roll clamp arms is driven by oil hydraulic cylinder

- ► Lifting of paper roll clamp arms is driven by oil hydraulic cylinder

- ► Paper guide roll and relevant brackets

-

-

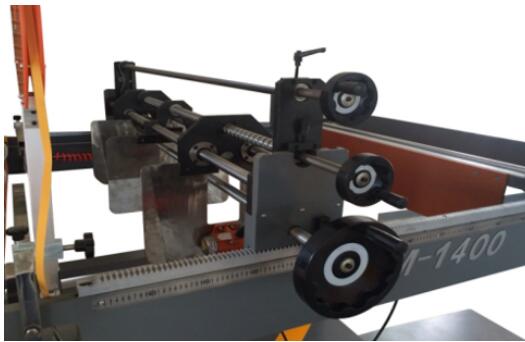

EPC SYSTEM (EDGE POSITION CONTROL)

- ► Hydraulic type, adopt accurate sensing valve for control, is driven by oil hydraulic cylinder

-

-

Anti-curve device

- ► Type: Adopt motor drive and high-speed adjustment.

- ► Anti-curve device: Anti-curve guide roll adopts patented design and efficient anti-curve treatment.

-

Paper pre-pressing part:

- ► Adopt electric control and inching mode, to make the pressing roll moving vertically, ensure proper positioning of feeding paper, and reduce the phenomenon of paper creping

Photoelectric tracking system (optional):

- ► Automatic edge leading: Hydraulic edge leading, paper edge, electric-eye tracking, paper control and adjustment, and edge correction system all need to be equipped with line and edge tracking Delivery control panel with icons for easy operation.

- ► Automatic cursor tracking slitting: Accurately locate the dual-servo drive system, so as to realize the dual-servo motor synchronization and adjustment.

- ► Automatic cursor electric-eye device: High-precision decibel electric-eye, to accurately locate paper color code and feed back to the TRIO tracking system.

Slitting part (optional):

- ► Type: Adjustable trimmed splitting knife and suction duct fan and air hose on both sides of waste paper edge.

- ► Upper knife: Adjustable rising and falling, switch type slitting knife, and paper cutting clearance can be adjusted manually

- ► Lower knife: Knife shaft fixed the upper and lower position, and paper cutting clearance can be adjusted manually.

- ► Fan: 1.5KW motor drive.

- ► Y type waste paper edge collection pipe and fixed frame.

Cutting part:

- ► Upper cutter roll: Adopt the UK cutter method to effectively reduce the load and noise of paper cutting as well as extend the service life of cutter. The part of upper cutter roll adopts stainless steel welding, precision finishing, and balance adjustment, to effectively reduce the vibration and noise of high- speed operation.

- ► Lower cutter holder: Adopt cast iron integrated forming casting, and combine with precision finishing, to have better stability.

- ► Drive roll: Roller 's surface adopts the expansion texture design and controls the pressurized clip paper of roller through the cylinder.

- ► Back cutting knife: Made of special alloy steel through precision finishing, thus having long service life; the blade is easy to adjust and calibrate.

- ► Safety cover: The machine stops automatically when the safety cover is open, so as to guarantee safety.

Man-machine interface:

- ► Electrical control system is easy to operate

- ► The cutting length, quantity and number of finished products can input directly

- ► The actual cutting length and cutting quantity can be displayed in real time

Static elimination equipment:

- ► Type: Plasma rod type, to eliminate the static electricity on paper.

- ► Main machine: Efficient static electricity.

-

Paper conveying equipment:

- ► Type: Horizontal multi-stage differential feeding, to produce separation count and paper stacking effect. (Conveyor belt: Nita brand, imported from Japan ).

- ► First conveyor section: Quickly separate and cut the paper.

- ► Second conveyor section: Can be controlled independently or jointly, and adjust the paper to feed out in imbrication type.

- ► Paper-out conveyor section: Refined paper separator, can be adjusted by the matched with paper width. pressurized feeding wheel to increase the stability of paper and avoid inclination of paper.

Automatic paper alignment and collection equipment:

- ► Type: Hydraulic lifting and stacking collection paper table, descend automatically when the paper stacks to a certain height.

- ► Paper alignment equipment: Electric type positive paper alignment mechanism; Electric type paper alignment mechanism on both sides; Turnover type rear retaining board mechanism; Hand-operated and both sides moveable of paper alignment mechanism.

Automatic counting label insert equipment:

- ► Type: Accurate counting transverse inserting.

- Function:

- ► Set the input the number of label in the soft-touch type computer interface, to insert the label according to the set value.

- ► 2.Sheet replenish function of non-conforming products.

Workshop:

-

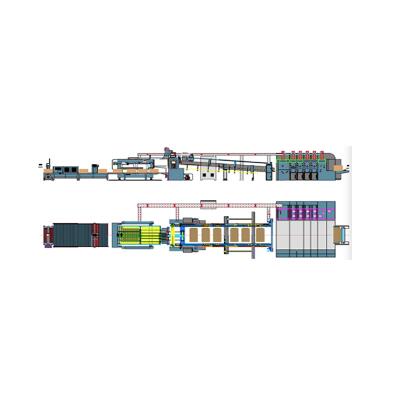

Corrugated Paperboard Production Line

-

Single Facer Line

-

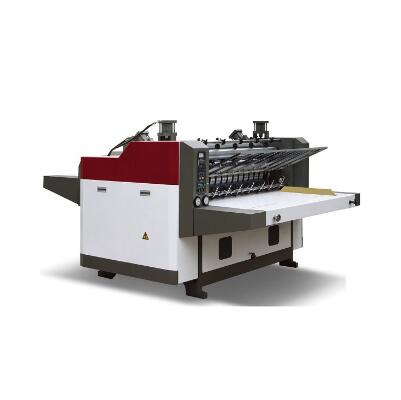

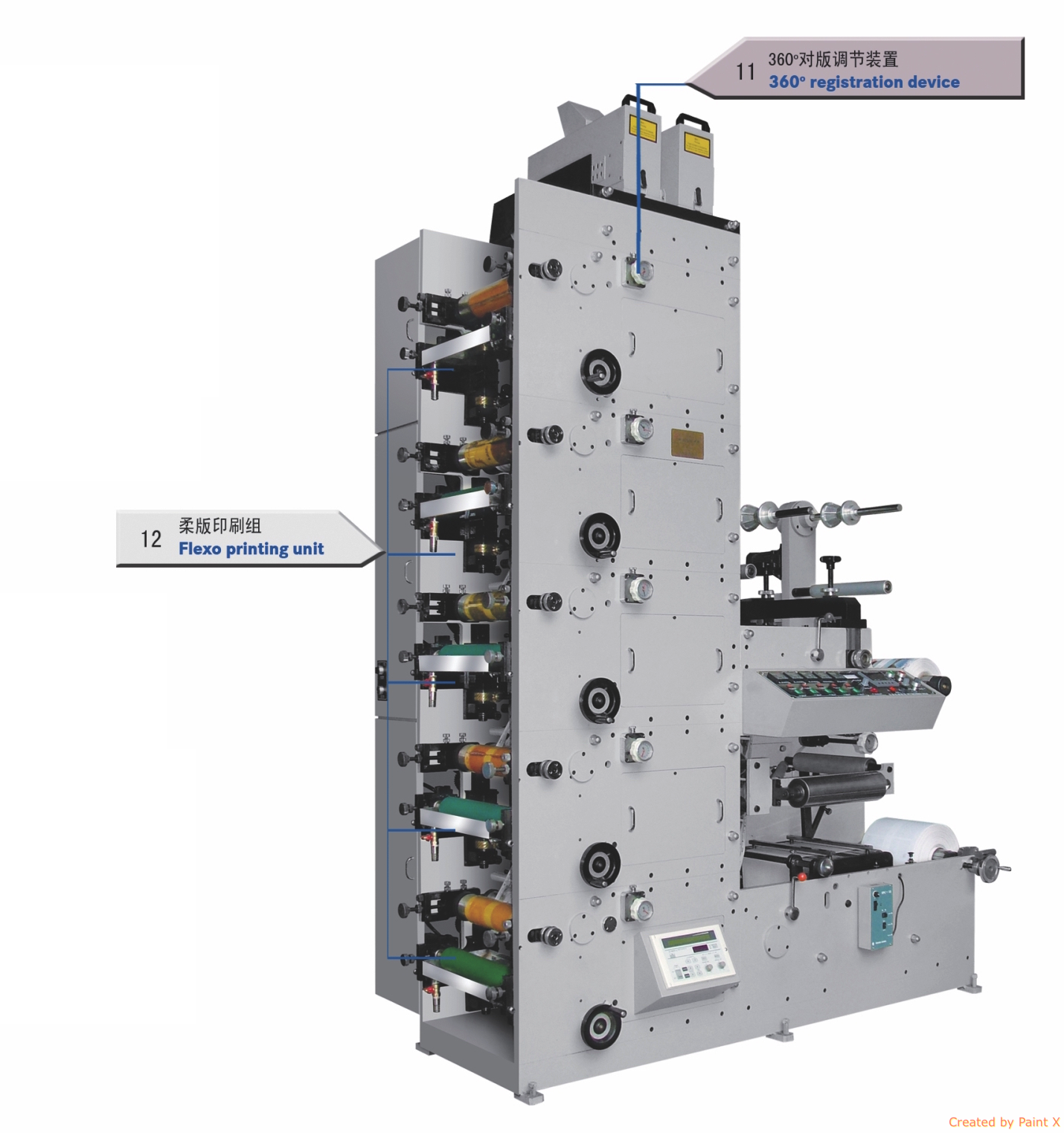

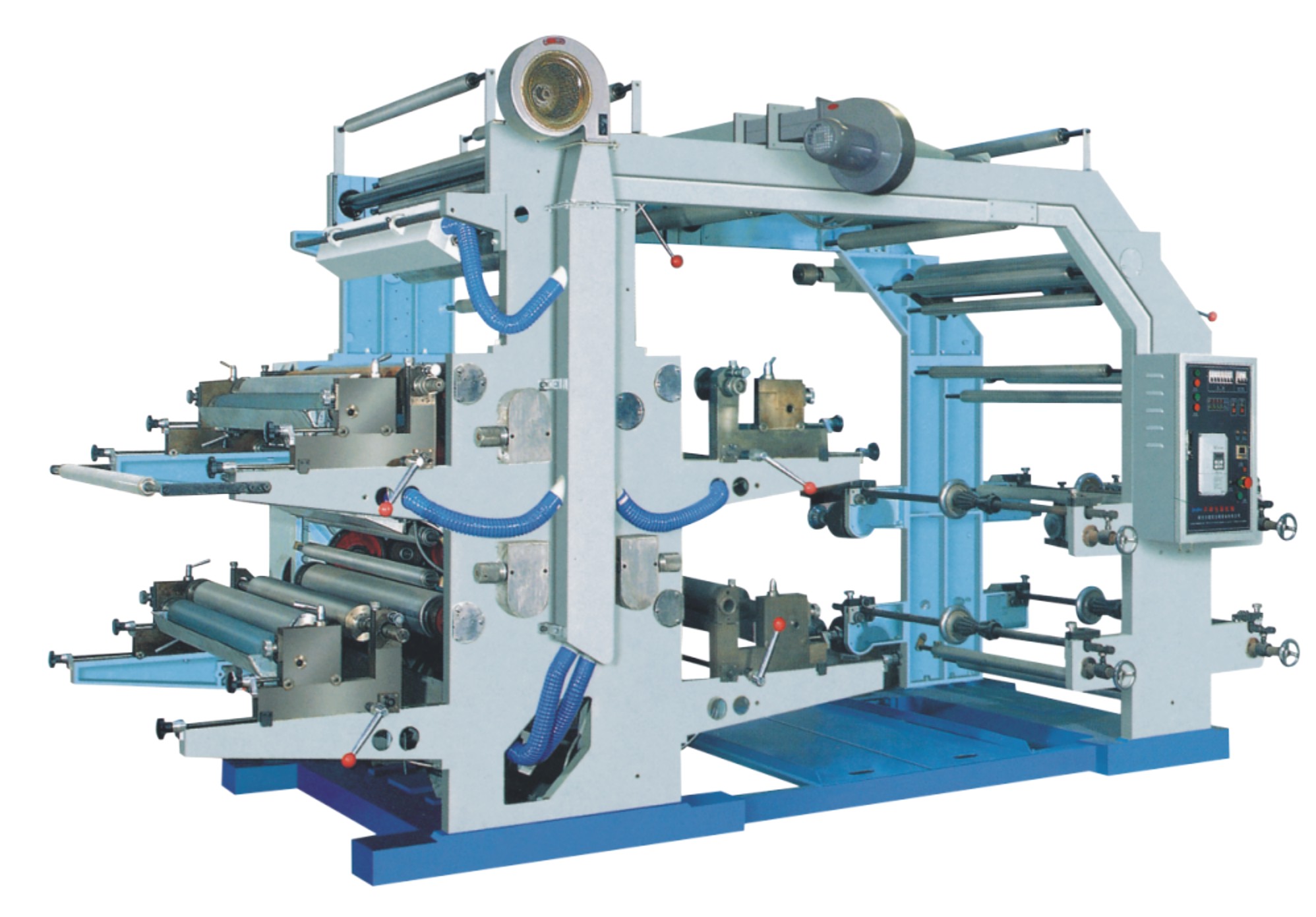

Flexo Printing Machine

-

Folder Gluer Machine

-

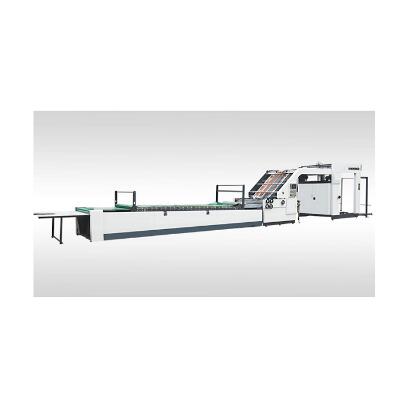

Flute Laminating Machine

-

Flat Die-Cutting Machine

-

Rotary Die-Cutting Machine

-

Carton Stitcher Machine

-

Paperboard Waste Baler Machine

-

Paperboard Stripping Machine

-

Single Facer Machine

-

Slitter Scorer

-

NC Cutter

-

Paper Roll Stand

-

Paperboard Stacker

-

Flexo Printing Plate Making Machine

-

Die-Cutting Mould Making Machine

-

Other Machines and Spare parts

-

Paper Roll Cutter

-

Window Patching Machine

-

Embossing machine

-

Slitting and Rewinding Machine

-

Paper Box Making machine

-

Digital Printing Machine