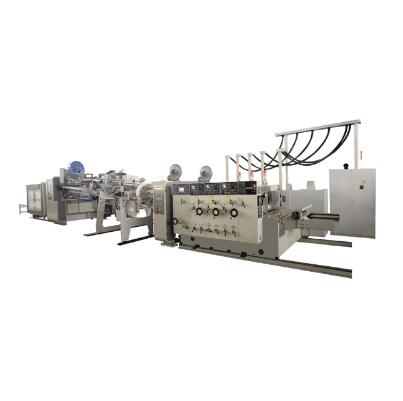

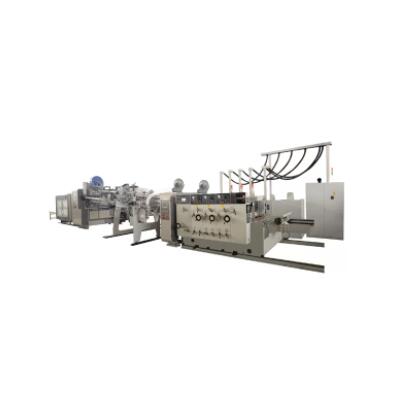

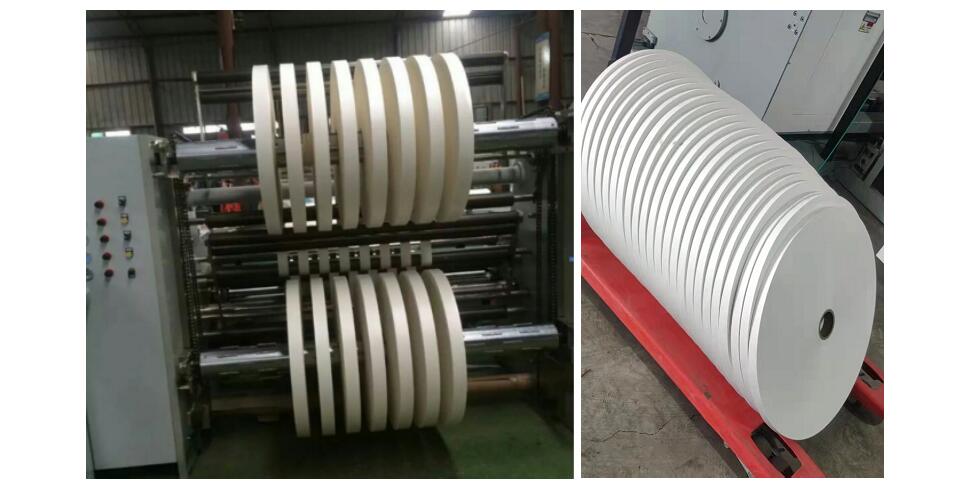

Automatic Slitting Rewinding Machine

Introduction:

Introduction:

This machine is used for slitting and rewinding various large rolling materials such as paper (40g/㎡-600g/㎡), cellophane paper, corrugated paper, bill paper, double-face adhesive tape, PVC, weave material, non-woven of cloth, OPP, PET, FILM, Copper foil etc.

More details:

High Speed Automatic Tension Paper Slitting and Rewinding Machine

Introduction:

This machine is used for slitting and rewinding various large rolling materials such as paper (40g/㎡-600g/㎡), cellophane paper, corrugated paper, bill paper, double-face adhesive tape, PVC, weave material, non-woven of cloth, OPP, PET, FILM, Copper foil etc.

Specification:

|

Model |

RYFQ-1800A |

|

Suitable working materials |

Paper sticker, paper, compound printing paper and so on |

|

Material thickness |

40-600gsm (paper) |

|

Max. Diameter of mother roll |

1600mm |

|

Max width of mother roller |

1800mm |

|

Paper roll core size |

3” or 6” |

|

Slitting width |

30-1800mm |

|

Max. Diameter after rewinding |

1300mm |

|

Precision of web-guiding |

±0.15mm |

|

Slitting speed |

350m/min |

|

Power |

32kw |

|

Machine weight |

7200kg |

|

Machine size |

3800*3400*2000mm |

|

Slitting knife |

10sets (can be required by customer) |

|

Rewinding shaft |

2units |

|

Hydraulic roll stand |

1unit |

Function description

Unwinding part

- 1. Adopts hydraulic roll stand loading. Magnetic brake. Automatic tension.

- 2. It does not need to input the material thickness, the proximity switch can inspect the unwinding diameter directly which near the transmission shaft. The machine can slow down according to the rest material, in this way, the worker can prepare for the next roller.

- 3. With the manual adjustment system, the unloading material tightness can be controlled. The adjustable range: +/-20mm

- 4. Adopt thread screw to move the frame left and right by motor to make the auto error-correction.

- 5. Corridor type feeding materials easily for operation.

- 6. Magnetic powder: 20KG, Brake: 2sets

Traction part

- The 7.5 KW servo motor drives the mirror surface and pinch roll

Waste paper recycle device

- Using motor to blow out the waste paper.

Rewinding part: (automatic loading and discharging, easily for operation)

- 1. Rewinding the cut material by upper and bottom double bearing.

- 2. Each rewinding shaft with 1 set of 11KW servo motor to drive the air shaft. The tension decided by the roll diameter. PLC controls SMC electric automatically to make all the sheet same thickness when do the multiple slitting. Because of the press roller, all the reels end face is smooth. it has the choice of pneumatic press roller and self-weight press roller. The screw type rewinding way can control the degree of the tightness of the finished products. With the increasing of the rewinding diameter, the servo motor speed goes down to extend the life of the air shaft, the air shaft never broken except the human factor.

- 3.It can choose the whole shaft tension without friction and the servo motor in torque control mode in PLC.

Rewinding and discharging: automatic up and down

-

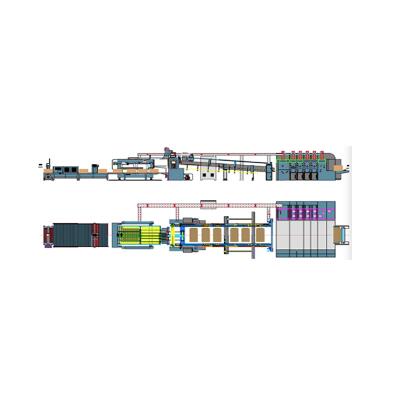

Corrugated Paperboard Production Line

-

Single Facer Line

-

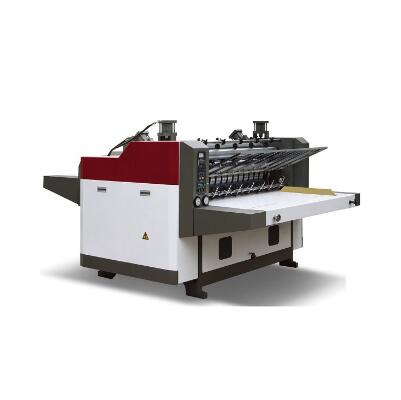

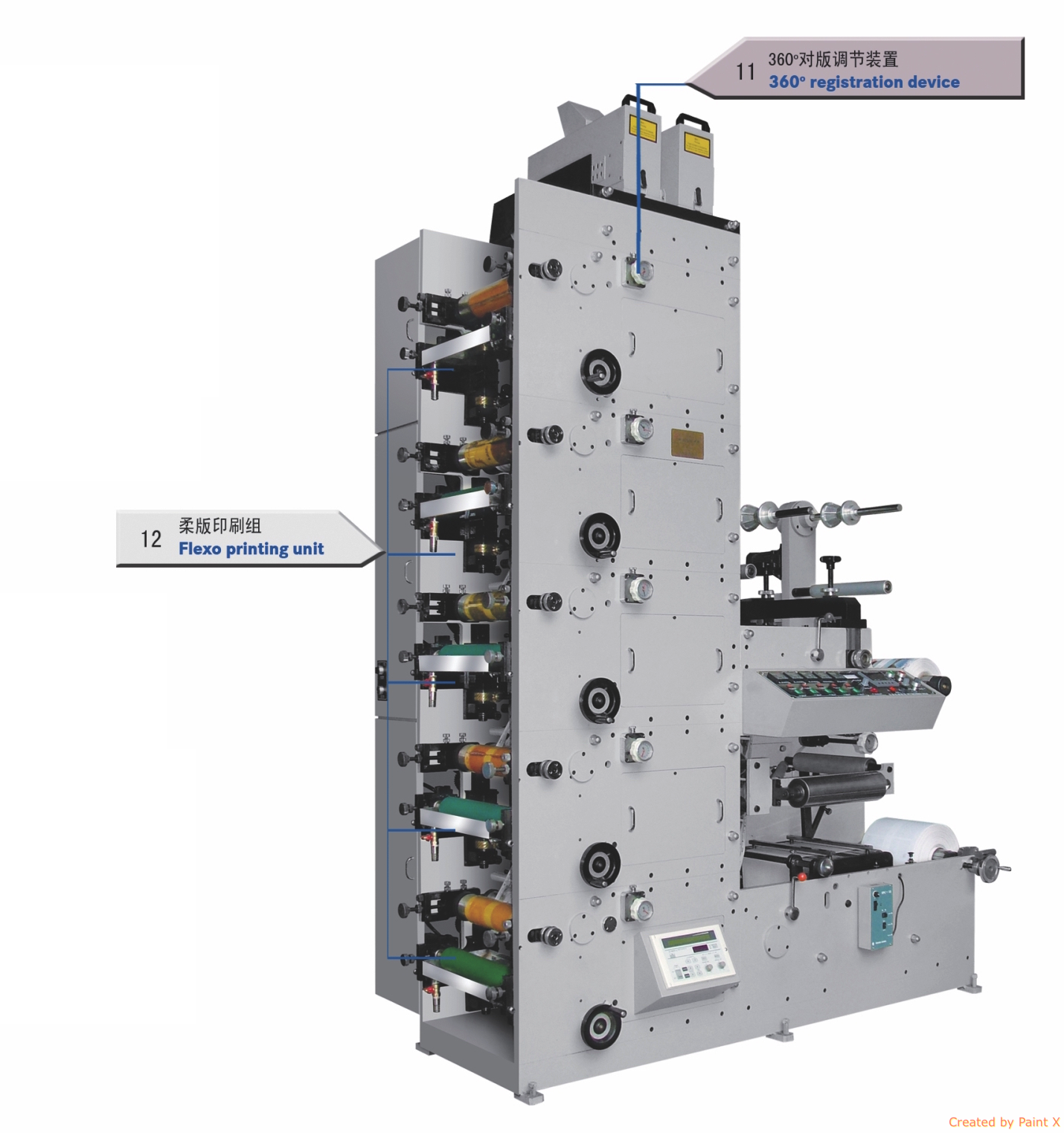

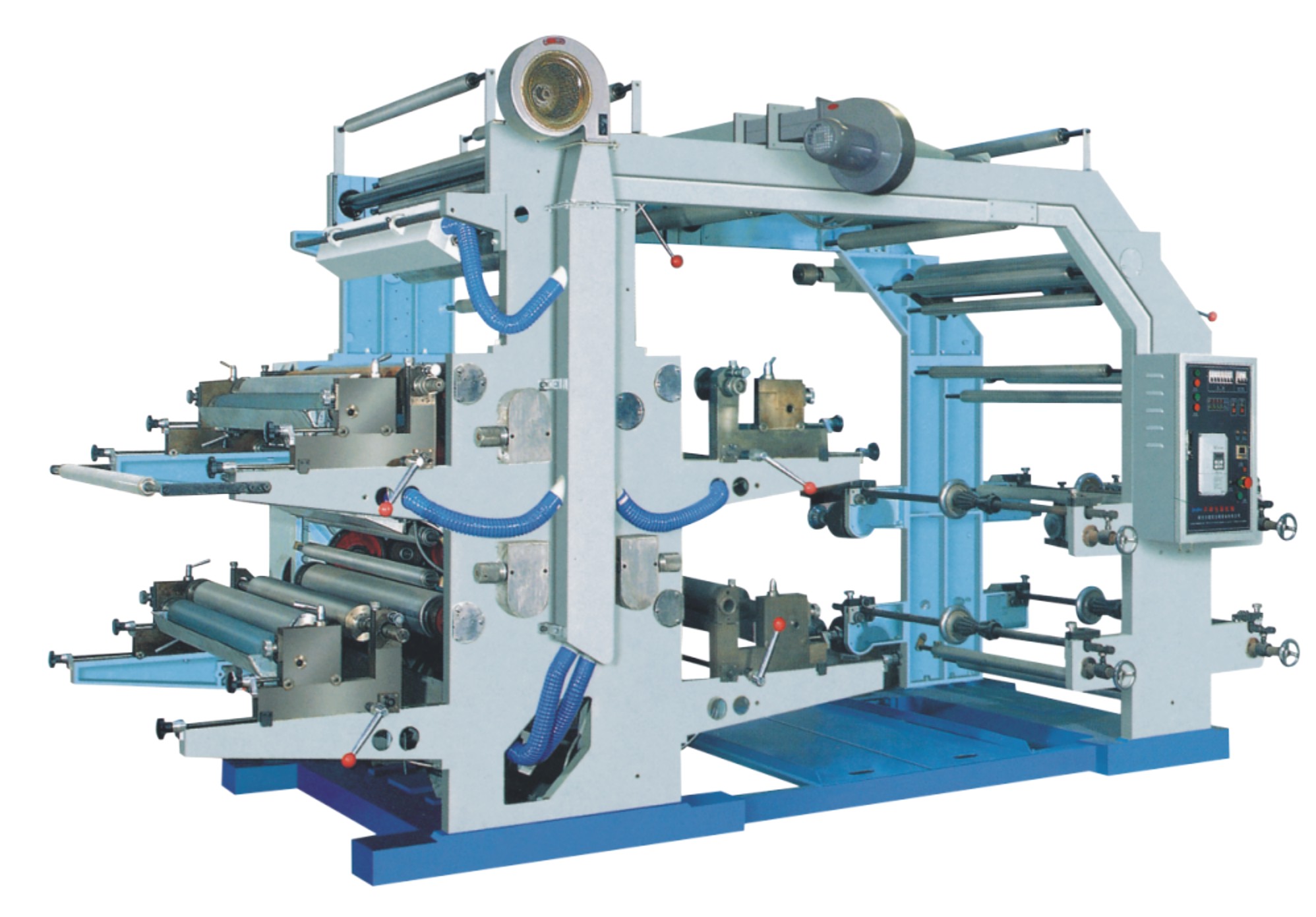

Flexo Printing Machine

-

Folder Gluer Machine

-

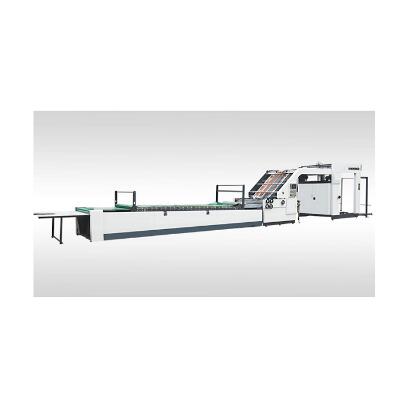

Flute Laminating Machine

-

Flat Die-Cutting Machine

-

Rotary Die-Cutting Machine

-

Carton Stitcher Machine

-

Paperboard Waste Baler Machine

-

Paperboard Stripping Machine

-

Single Facer Machine

-

Slitter Scorer

-

NC Cutter

-

Paper Roll Stand

-

Paperboard Stacker

-

Flexo Printing Plate Making Machine

-

Die-Cutting Mould Making Machine

-

Other Machines and Spare parts

-

Paper Roll Cutter

-

Window Patching Machine

-

Embossing machine

-

Slitting and Rewinding Machine

-

Paper Box Making machine

-

Digital Printing Machine